Rubber Technology & Development Department

The mandate of the department is to carry out Research and Development work on overall aspects of Rubber Technology to upgrade the rubber based product industries in Sri Lanka in order to acquire the global standards, thereby making Sri Lankan rubber products competitive in the international markets. Additionally, the department undertakes testing of mainly rubber compounds and products according to international standards on request from the industry. Apart from the above, training programs on rubber based products manufacture are conducted, especially for SME’s to expand the rubber products manufacturing industry in Sri Lanka.

Development of novel recycling processes for latex or dry rubber based compound / product waste

Blending of virgin and reclaimed rubbers to manufacture rubber products has increased over the past years due to the growing concern about the effect of rubber waste on the environment and the rise in the costs of synthetic rubbers. Acrylonitrile-butadiene rubber or nitrile rubber (NBR) glove waste was reclaimed using a readily available, environmental friendly, low cost amino compound and virgin NBR / reclaimed NBR glove waste composites suitable for oil resistant applications were developed. Work is in progress to commercialize this recycling process and to develop novel recycling processes for natural rubber (NR) based glove and cast product waste, polyurethane foam waste and ethylene-propylene-diene monomer (EPDM) product waste.

Senior Research Officer

W D M Sampath, BSc(SL), M.Phil (SL), PhD (SL)

wikcramage[at]yahoo.com

+94 77 2548221

Mr. W.D.M. Sampath, B.Sc. (Sp.) (Sabaragamuwa, SL) and M.Phil. (Moratuwa, SL) is a Senior Research Officer at the Rubber Technology & Development Department, Rubber Research Institute of Sri Lanka. Mr. W.D.M. Sampath has eight years of research experience in the field of “Rubber Technology”. His current research areas include development of dry rubber based blends of natural and synthetic rubbers for various applications, thermoplastic elastomers, modified natural fibre filled green rubber composites, cellular rubber products with dry rubber for special applications, rubber composites with coconut husk materials for special applications, functional graphite and graphite derivatives filled natural rubber composites for electrical and thermal conductivity applications and rubber composites with nano materials. He has 42 international and local publications to his credit. He won the Technology Award of Excellence from the National Science Foundation in 2016 and High Minds Lead Mind Award in 2019 for the Best Rubber Industry Participation in the Leadership and Capacity Building Training Programme for “Young Rubber Industry Professionals”.

Research Officer

Mrs. U. Aloka Weerasinghe. B.Sc.

aloka.weerasinghe[at]gmail.com

+94 77 7126796

Mrs. U.Aloka Weerasinghe, B.Sc. (Sp.) (Colombo, SL) is a Research Officer at the Rubber Technology & Development Department, Rubber Research Institute of Sri Lanka. Mrs. U.Aloka Weerasinghe has one year research experience in the field of “Rubber Technology”. Her current research areas include development of dry rubber based blends of natural and synthetic rubbers for various applications, cellular rubber products with dry rubber for special applications, modified natural fiber filled green rubber composites and rubber composites with nano materials.

- Development of natural rubber (NR) / polyvinyl acetate (PVAc) latex blends with excellent strength properties.

- Manufacture of a novel creature (one of the characters required for production of a space movie) out of NR latex foam.

- Development of natural rubber latex based flowers and leaves for floral décor.

- Development of multi-coloured shoe-soles with different surface designs out of dipped products waste / rejects.

- Development of the cost effective, environmental friendly “Power Mat” out of dipped product waste for various applications (weed controlling device for agricultural / horticultural fields, mat for playgrounds, partial replacement for virgin rubber in rubber composites)

- Development of rubber composites with plant based natural oils as an alternative for rubber composites with petroleum based aromatic oils.

-

Development of locally available dolomite containing rubber composites for different applications,

e.g. middle layer of solid tyres, floor mats.

- Improvement of surface properties of natural rubber latex films with linseed oil.

- Development of dry rubber based composites with modified natural oil as a replacement for aromatic oil.

- Development of environmental friendly, mechano-chemical modification techniques for rubber waste (NR and NBR) using readily available, low cost chemicals as well as natural products.

- Development of surface treated coconut fibre filled rubber composites.

- Development of palmyrah fibre filled rubber composites for solid tyres.

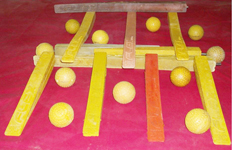

- Development of a light weight rubber stump for cricket practicing purpose.

- Development of a stopper band compound using a NR/EPDM composite.

- Development of a styrene-butadiene rubber based light weight rubber ball with low resilience, high abrasion resistance and high hardness for cricket practicing purpose.

- Development of a high performance lighter weight prosthetic foot based on hybrid nano-material filled natural rubber nano-composite

- Development of NR latex based adhesives for paper and shoes.

- Development of non-conductive NBR based compound for grommets used in assembling of electric cables.

- Development of SBR based compound for condenser end mount and wiring bunch bush.

- Development of EPDM based compound for suction end mount.

- Development of pyrogenic carbon filled NR/SBR composites for tyre treads.

- Development of surface treated natural fiber (palmyra, watakeiya) filled rubber composites for solid tyres.

- Production of NR latex foam with antioxidant and antimicrobial effects using aloe vera.

- Development of a NR and low density polyethylene (LDPE) blend with improved properties suitable for roofing applications.

- Development of a synthetic rubber based compound with good heat, abrasion and oil resistance for the sliding shoe of crawlers.

- Development of NBR, SBR and EPDM based compounds for electrical components.

- Production of a non-toxic, light coloured NR based transparent teething ring.

- Development of a nitrosamine safe NR latex based adhesive for infant items.

- Production of NR or MG rubber (methyl methacrylate grafted rubber) / neoprene rubber (CR) based adhesives.

- Development of modification processes for product waste of synthetic polymers.

- Development of NR based micro-cellular rubber sheets for special applications.

- Development of NR based composites with durian husk fibres.

- Development of NR based composites using synthesized micro and nano fibres of coir.

- Development of NR based compounds with low hardness for rubber mounts.

- Development of can sealant and foam rubber adhesive compounds.

- Development of novel gloves to protect against the Covid-19 pandemic.

- Development of a NR latex compound as a coating material for tents made out of fabric.

- Development of a NR latex based binder for rubber product waste.

- Development of a NR latex based cast product for marine applications.

- M.K. Mahanama – Presidential Merit Award in 2003 for the invention titled “Natural Rubber Latex based Flowers for Floral Décor”.

- M.K. Mahanama – Bronze Medal in the “Industrial Category” at the “International Inventors Exhibition” held in Geneva, Switzerland in 2006 for the invention titled “Natural Rubber Latex based Flowers for Floral Décor”.

- The staff of the department was actively involved in organizing the RRISL stall, which won first place at the “Viskam Dakma” exhibition and trade fair held in 2006.

- The staff of the department was actively involved in organizing the Ministry of Plantation Industries stall

- under Agricultural Cluster, which won first place at the “Deyata Kirula” national development exhibition 2007.

- A. Nugawela, D.G. Edirisinghe and M.K. Mahanama - National Science and Technology Award 2010 in the category, “Development of Eco Material / Eco-friendly Processes for the Industry” was received for the “Power Mat” developed out of dipped products waste.

- A. Nugawela, D.G. Edirisinghe and M.K. Mahanama - Presidential award 2010 for the best invention in the “Environment” category was received for the “Power Mat” developed out of dipped products waste.

- M.G.S.M. Wijeratne, L.M.K. Tillekeratne, W.M.G. Seneviratne, D.G. Edirisinghe, W.D.M. Sampath and S.L.G. Ranjith - Best paper award under the theme “Rubbers, Rubber Blends and Applications”- Evaluation of the Suitability of Local Dolomite as a Replacement for Calcite in Solid Tyre Manufacture”, IIUPST 2012.

- B.H.K.M. Silva, D.G. Edirisinghe and M.K. Mahanama – Best poster award - “Improvement of Surface Properties of Natural Rubber Latex Films with a Novel Plasticiser”, IIUPST 2012.

- W.D.M. Sampath, S.M. Egodage and D.G. Edirisinghe - Best abstract under the theme “Polymer Science” – “Effect of a Titanate Coupling Agent on Chemical and Ageing Properties of Calcium Carbonate Filled

- Natural Rubber and Low Density Polyethylene Composites”, IIUPST 2015.

- D.G. Edirisinghe - Merit Award from the Plastics & Rubber Institute of Sri Lanka in 2015 for the significant contribution to the development and growth of the polymer industry in Sri Lanka.

- U.N. Ratnayake, D.G. Edirisinghe, W.D.M. Sampath and D.G.M.J. Abeywardena - Technology Award from the National Science Foundation in 2016 for the project titled “High Performance Lighter Weight Prosthetic Foot based on Hybrid Nano-material Filled Natural Rubber Nano-composite”.

- D.G. Edirisinghe, N.N. Ratnawardhana, M.K. Mahanama and D. Gunathilaka - Presidential Merit Award in the “Chemistry” category for the developed “Mechano-chemical Reclaiming Process (Oreclaim) for Ground Rubber Tyre” using a natural product (Patented in 2016).

- D.G. Edirisinghe. Award for “Scientific Excellence” in the Rubber Sector during 2016-2018 received on 04.11.2019 at the Seventh Symposium on Plantation Crop Research held at the Marino Beach Hotel, Colombo.

- I.H.K Samarasinghe, D.G. Edirisinghe, S. Walpalage and S. M. Egodage (2019). Best Paper Award - “Effect of Nitrosamine Safe Diisopropyl Xanthogen Polysulfide Accelerator on Cure and Static Mechanical Properties of Natural Rubber Compounds”, Seventh Symposium on Plantation Crop Research, Marino Beach Hotel, Colombo, 4-6th November, 2019.

- Y.G. Kondarage, H.M.J.C. Pitawala, T. Kirushanthi, D. Edirisinghe, Thusitha N. Etampawala. The paper titled “Ceramic waste based natural rubber composites: An exciting way for improving mechanical properties” received the SLAAS - Section D – Life & Earth Sciences – Second Prize at the SLAAS Annual Sessions held in December 2019.

- W.D.M. Sampath, C.A.N. Fernando and D.G. Edirisinghe (2022). “Effect of copper grafted graphite loading on cure characteristics of natural rubber composites” - 2nd International Conference on Science and Technology, South Eastern University of Sri Lanka, 24th of August 2022 – W.D.M. Sampath received the Best Presenter Award.

- M.K. Mahanama - Development of NR latex based flowers for floral décor (Patent No. 12696 - 2001).

- M.K. Mahanama and D.G. Edirisinghe - Development of shoe soles out of dipped products waste/ rejects (Industrial Design No. 7487 - 2005 ).

- M.K. Mahanama and D.G. Edirisinghe - Multi-coloured shoe soles with different surface designs, produced solely out of dipped products waste / rejects (Patent No. 13604 - 2009).

- A. Nugawela, M.K. Mahanama and D.G. Edirisinghe - Weed control power mats based on natural rubber dipped products waste (Patent No. 14908-2010).

- Mahanama, M.K., Seneviratne, P. and Edirisinghe, D.G. - “Cost Effective Environmental Friendly Nursery Bag Produced out of Waste” (2010).

- D.G. Edirisinghe, M.K. Mahanama, M.K.N.N. Rathnawardhana and R.P.D. Gunathilaka - “A Mechano-chemical Reclaiming Process (Oreclaim) for Ground Rubber Tyre” (Patent No. 17588 - 2016).

- Development of novel recycling processes for latex or dry rubber based compound / product waste.

- Development of cellular rubber products with latex / dry rubber for special applications.

- Development of dry rubber blends / composites of natural and synthetic rubbers for different applications

- Development of dry rubber composites with waste materials for different applications.

- Development of rubber composites with coconut husk materials for special applications.

- Synthesis of natural nano-fibers and development of rubber composites with nano-fibers

The department provides the following services

Journal Publications

- J.K. Premachandra, D.G. Edirisinghe and M.I.A. De Silva, “A Novel Reclaiming Agent for Ground Rubber Tyre (GRT) Part 1: Property Evaluation of Virgin Natural Rubber (NR) / Novel Reclaimed GRT Blend Compounds” – Progress in Rubber, Plastics & Recycling Technology, 2011,Vol.27, No.1.

- D.G. Edirisinghe, M.I.A. De Silva and J.K. Premachandra, “A Novel Reclaiming Agent for Ground Rubber Tyre (GRT) Part II: Property Evaluation of Virgin Natural Rubber (NR) / Novel Reclaimed GRT Revulcanisates” – Progress in Rubber, Plastics & Recycling Technology, 2011, Vol.27, No.3.

- Chandrasekera, Ganga, Mahanama, M.K., Edirisinghe, D.G. and Karunanayake, L., “Epoxidized Vegetable Oils as Processing Aids and Activators in Carbon Black Filled Natural Rubber Compounds” – Journal of the National Science Foundation of Sri Lanka, 2011, Vol. 39, pp.243-250.

- T.A.A.I Siriwardena, S.M.Egodage and D.G. Edirisinghe (2012) “The Effect of Silica to Carbon Black Ratio on Properties of a Tubeless Tyre Inner Liner Compound Prepared with a Blend of Chlorobutyl Rubber and Natural Rubber”. The Institution of Engineers (IESL), Sri Lanka, Transactions 2012, Vol. 1, Part B, p.290-296.

- Sampath W.D.M, Edirisinghe D.G and Wettasingha P.C., “Property improvement of natural rubber and low density polyethylene blends by compatibilizing with silane coupling agent”. Journal of Applied Science and Agriculture (JASA) (Special issue ICPRC 2014 International Conference on Plastics, Rubber and Composites), 2014.

- W.D.M Sampath, S. M. Egodage and D.G. Edirisinghe, “Effect of blend ratio on properties of natural rubber / low density polyethylene blends”. The Institution of Engineers (IESL), Sri Lanka, Transactions 2014, Vol. 1, Part B, p.247-253.

- G.M.P. Perera and D.G. Edirisinghe, “Development of a Highly Effective Room Temperature Vulcanizing System for Natural Rubber Latex based Compounds”. The Journal of the Plastics and Rubber Institute of Sri Lanka, 2014, Vol.14.

- D.G. Edirisinghe, W.D.M. Sampath and P.C. Wettasinghe, “Effect of Latex Coated Coconut Fibre on Cure Characteristics and Physico-mechanical Properties of Natural Rubber-Coir Composites”, Journal of the Rubber Research Institute of Sri Lanka, 2015, Vol. 95, p.1-13.>

- W.D.M. Sampath, D.G. Edirisinghe and S.M. Egodage, “Improvement of physico-mechanical properties of calcium carbonate filled natural rubber and low density polyethylene blends with titanate coupling agent” – IEEE Xplore, DOI:10.1109 / MERCon. 2015, 7112350, pp-228-233.

- W.D.M. Sampath and D.G. Edirisinghe, “Effect of waste LDPE on properties of maleic anhydride treated NR/LDPE/waste LDPE composites” – The Journal of the Plastics and Rubber Institute of Sri Lanka, 2016, Vol.15, p. 31-41

- J.C. Jayawarna and D.G. Edirisinghe, “Use of Modified Solid Rubber Waste in Dry Rubber based Products as a Step towards Sustainability”– The Journal of the Plastics and Rubber Institute of Sri Lanka, 2017, Vol.16.

- Y.G. Kondarage, H.M.J.C. Pitawala, T. Kirushanthi, D. Edirisinghe, Thusitha N. Etampawala (2018) -“Ceramic waste-based natural rubber composites: An exciting way for improving mechanical properties” – J. Adv. Chem.Sci., Volume 4, Issue 3, pp.576-582.

- T. Kirushanthi, Thusitha N. Etampawala, Dilhara Edirisinghe, Jagath Pitawala, D.R. Ratnaweera (2018) – “Development of agro-industrial waste reinforced natural rubber composite: A potential formulation for rubber flooring product” - J. Adv. Chem. Sci., Volume 4, Issue 3, pp.571-575.

- W.D.M. Sampath, S.M. Egodage and D.G. Edirisinghe (2019) – “Effect of an organotitanate coupling agent on properties of calcium carbonate filled low-density polyethylene and natural rubber composites” – J. Natn. Sci. Foundation Sri Lanka, 47 (1), pp. 17-27.

- Sampath, W.D.M., Egodage, S.M., and Edirisinghe, D.G., 2019. Effect of Peroxide Loading on Properties of Natural Rubber and Low-density Polyethylene Composites. Journal of Physical Science, 30(3),49–69, https://doi.org/10.21315/jps2019.30.3.4.

- Sampath, W.D.M., Perera, I.D., Edirisinghe, D.G. and Abhayawardhana, V.G.M.J., 2019. Effect of waste polyethylene on properties of methyl salicylate treated natural rubber/low density polyethylene/waste polyethylene composites. Journal of the Rubber Research Institute of Sri Lanka, 99, pp.95-104.

- Sampath W.D.M., Sandaruwan P.D., Edirisinghe D.G. and Sudusingha Y.C.Y. (2020). “Effect of Artocarpus Heterophyllus Latex on Properties of Calcium Carbonate Filled Natural Rubber/Low Density Polyethylene/Waste Polyethylene Composites”- Phys. Sci. & Biophys. J., 2020, 4(1): 000140.

- I.H.K. Samarasinghe, S. Walpalage, D.G. Edirisinghe and S.M. Egodage – “Study on Sulfur Vulcanized Natural Rubber Formulated with Nitrosamine Safe Diisopropyl Xanthogen Polysulfide/Tertiary Butyl Benzothiazole Sulphenamide Binary Accelerator System”-Progress in Rubber, Plastics & Recycling Technology. First published online on December 11, 2020.

- D.M.E. Senewirathna, W.D.M. Sampath, U.A. Weerasinghe and D.G. Edirisinghe (2020) – “Evaluation of Cure Characteristics and Tensile Properties of Natural Rubber Compounds Filled with Coir Fiber Ranging from Micro to Nano Scale” - The Journal of the Plastics and Rubber Institute of Sri Lanka, Volume 19, 58-68.

- R.R.W.M.U.G.K. Wadugodapitiya, H.G.I.M. Wijesinghe, D.G. Edirisinghe, G.R.V.S. Gamlath, A.M.W.K. Seneviratne and T.R.A.W.M.C.G. Bandara (2020) – “Potential of using carbon black and silica extracted from rice husk ash as combined filler system for acrylonitrile-butadiene rubber compounds”- The Journal of the Plastics and Rubber Institute of Sri Lanka, Volume 19, 33-41.

- Amali Weerakoon, Laleen Karunanayake and Dilhara Edirisinghe (2020) – “Extraction of Polyphenols from Banana Pseudo Stem: Influence of Temperature and pH Value on Optimization of Total Phenolic Yield” - The Journal of the Plastics and Rubber Institute of Sri Lanka, Volume 19, 69-74.

- H.G.I.M. Wijesinghe, G.R.V.S. Gamlath, A.M.W.K. Senevirathna, D.G. Edirisinghe, R.R.W.M.U.G.K. Wadugodapitiya, T.A.R.W.M.M.C.G. Bandara and B.S.N. Bandara (2021) – “Effect of Pre-Blending and Phase-Mixing Methods on Properties of Natural Rubber and Acrylonitrile Butadiene Rubber Blends Filled with Nano Silica Extracted from Rice Husk Ash” – Journal of Nanoscience and Technology, Volume 7, Issue 1, 928–932.

- Perera K.I.D.P., Edirisinghe D.G. and Karunanayake L. (2021) – “Characterisation of Blends of Virgin Nitrile Rubber and Compounded Nitrile Rubber Latex Waste Reclaimed with Urea – Part I : Cure Characteristics”, Progress in Rubber, Plastics & Recycling Technology, Vol. 37, Issue 2, 115-130 (First published online on April 23, 2020).

- K.I.D.P. Perera, D.G. Edirisinghe and Laleen Karunanayake (2021) – “Characterisation of Blends of Virgin Nitrile Rubber and Compounded Nitrile Rubber Latex Waste Reclaimed with Urea - Part II : Physico-Mechanical Properties”, Journal of Advanced Chemical Sciences, Vol. 7, Issue 3, 733-737.

- Sampath Wickramage Don, C.A.N. Fernando and D.G. Edirisinghe (2021) – “Review on Carbon Black and Graphite Derivatives-based Natural Rubber Composites”, Journal of Advances in Technology, Vol. 1, Issue 1, 101-126.

- U.A. Weerasinghe, W.D.M. Sampath, D.G. Edirisinghe and T.G.K.H. Madushika (2021). The Journal of the Plastics and Rubber Institute of Sri Lanka – “Evaluation of Cure Characteristics and Physico-mechanical Properties of Treated Oil Palm Fibre based Natural Rubber Composites”, Vol. 20, pp. 89-94.

- Kalani D. Edirisinghe, D.G. Edirisinghe, M.K. Mahanama, L. Karunanayake and S.D.M. Chinthaka (2021). The Journal of the Plastics and Rubber Institute of Sri Lanka – “Evaluation of Suitability of Urea as a Preservative in Low Ammonia Centrifuged Latex Manufacture”, Vol. 20, pp. 98-105.

- I.H.K Samarasinghe, S. Walpalage, D.G Edirisinghe and S.M. Egodage (2022) – “The use of Diisopropyl Xanthogen Polysulfide as a potential Accelerator in Efficient Sulfur Vulcanization of Natural Rubber Compounds”, Journal of Applied Polymer Science, 139(18), 52063.

- H.G.I.M. Wijesinghe, T.N.B. Etampawala, D.G. Edirisinghe, G. R. V. S. Gamlath, R. R. W. M. U. G. K. Wadugodapitiya, T. A. R. W. M. M. C. G. Bandara (2022) – “Properties of Rice Husk Ash Silica Filled Natural Rubber and Acrylonitrile-butadiene Rubber Blends”, Journal of Agricultural Sciences – Sri Lanka, 17(1), pp.1-18. The Faculty of Agricultural Sciences of the Sabaragamuwa University of Sri Lanka.

- D.S. Wijewardane, M.A.S.R. Seneviratne, S. Siriwardena, D.G. Edirisinghe and Y.C.Y. Sudusingha (2022) – “Preparation of Skim Natural Rubber and Polypropylene Blends via Melt Blending: A Study on Processability” Progress in Rubber, Plastics & Recycling Tchnology, First published online on May 25.

Conference Proceedings

- W.D.M. Sampath, S.M. Egodage and D.G. Edirisinghe (2015) “Effect of a Titanate Coupling Agent on Chemical and Ageing Properties of Calcium Carbonate Filled Natural Rubber and Low Density Polyethylene Composites”,Proceedings of the IIUPST 2015, University of Jayewardenepura, Nugegoda, 3-4th April, 2015, p.10.

- C.N. De Silva, D.G. Edirisinghe and R.S. Dharmakeerthi (2015) “Effect of Partial Replacement of Carbon Black with Pyrogenic Carbon on Properties of Tyre Tread Compounds”, Proceedings of the IIUPST 2015, University of Sri Jayewardenepura, Nugegoda, 3-4th April, 2015, p.19.

- J.C. Jayawarna and D.G. Edirisinghe (2015) “Reclaiming of Natural Rubber Latex Product Waste by a Mechanochemical Process for Production of Solid Tyre Treads”, Proceedings of the IIUPST 2015, University of Sri Jayewardenepura, Nugegoda, 3-4th April, 2015, p.20

- W.D.M. Sampath, D.G. Edirisinghe and S.M. Egodage (2015) “Improvement of Physico-mechanical Properties of Calcium Carbonate Filled Natural Rubber and Low Density Polyethylene Blends with Titanate Coupling Agent” Proceedings of the MERcon 2015, University of Moratuwa, Moratuwa, 7-8th April, 2015, pp. 82-83

- W.D.M Sampath, S.M. Egodage and, D.G. Edirisinghe (2015) “Effects of titanate based coupling agent and mixing methods on properties of natural rubber and low density polyethylene blends”. Proceedings of International Research Sessions, Peradeniya University of Sri Lanka, 5th-6th November, 2015.

- W.D.M. Sampath, S.M. Egodage and D.G. Edirisinghe (2015) “The effect of coupling agent and mixing methods on properties of natural rubber and low density polyethylene blends”. Proceedings of International Rubber Conference, Ho Chi Minh City, Vietnam, 2nd -3rd November, 2015

- T. Kirushanthi, D.G. Edirisinghe, C.K. Jayasuriya (2016) “Investigation on Suitability of Banana Fiber as a Filler Material in Natural Rubber Latex-Based Household Gloves”, Proceedings of the Research Symposium of Uva Wellassa University, 28th January, 2016.

- W.D.M. Sampath, D.G. Edirisinghe and S.M. Egodage (2016) “Property Improvements of Natural Rubber and Low Density Polyethylene Blends through Dynamic Vulcanization”, Proceedings of the 6th Symposium on Plantation Crop Research, Volume 2, 3-4th November, 2016

- Perera K.I.D.P. and Edirisinghe D.G. (2017) “Reclaiming of Acrylonitrile-Butadiene Rubber Waste using an Amino Compound for Oil Resistant Applications”, Proceedings of the IIUPST 2017, University of Sri Jayewardenepura, Nugegoda, 14-15th April, 2017

- K.K. Kalubovila, R.C.W.M.A. Nugawela, D.G. Edirisinghe and S.L.G. Ranjith (2017) “Development of an Ammonia Free, Environmental Friendly Preservative System for Centrifuged Natural Rubber Latex”, Proceedings of the 16th Agricultural Research Symposium of Wayamba University of Sri Lanka, 8-9th November, 2017

- T. Kirushanthi, H.M.J.C. Pitawala, D. Edirisinghe, D.R. Ratnaweera and T.N.B. Etampawala (2018) “Silica from Rice Husk as an Alternative to Commercially available silica fillers in tyre compounding”, Proceedings of the IRSUWU, Uva Wellassa University, 1-2nd February, 2018.

- Y.G. Kondrage, H.M.J.C. Pitawala, K. Thangavel, D. Edirisinghe and T.N.B. Etampawala (2018) “Ceramic Waste – Based Natural Rubber Composites: An Exciting Way for Improving Mechanical Properties”, Proceedings of the IRSUWU, Uva Wellassa University, 1-2nd February, 2018

- K.C. Samaraweera, H.G.I.M. Wijesinghe, T.N.B. Etampawala, D.G. Edirisinghe and A.M.W.K. Seneviratne (2018) “Silica Extracted from Rice Husk Ash as an Effective Reinforcing Filler for Natural Rubber Composites”, Proceedings of the IRSUWU, Uva Wellassa University, 1-2nd February, 2018

- K.P.I. Madushika, H.G.I.M. Wijesinghe, D.G. Edirisinghe and A.M.W.K. Senevirathna (2019) “Influence of Partial Replacement of Carbon Black with Areca Nut Husk Fibre on Properties of Natural Rubber Composites”, Proceedings of the International Research Conference, Uva Wellassa University, February 7-9, 2019

- T. Kirushanthi, H.M.J.C. Pitawala, D. Edirisinghe, D.R. Ratnaweera and T.N.B. Etampawala (2019) “Development of polyurethane based composite using plastic waste of PET bottles and agro waste” Proceedings of the International Research Conference, Uva Wellassa University, February 7-9, 2019, p.457

- W.D.M. Sampath, S.M. Egodage and D.G. Edirisinghe (2019) “Effect of recycled polyethylene (rPE) on properties of titanate coupling agent treated natural rubber (NR) / low density polyethylene (LDPE) / rPE composites, Proceedings of the 3rd ICSTR Dubai – International Conference on Science & Technology Research, 26-27 February, 2019, Flora Grand Hotel, Deira, Dubai, United Arab Emirates, p. 14

- I.H.K. Samarasinghe, D.G. Edirisinghe, S.Walpalage and S.M. Egodage “Effect of Nitrosamine Safe Diisopropyl Xanthogen Polysulfide Accelerator on Cure and Static Mechanical Properties of Natural Rubber Compounds” Proceedings of the Seventh Symposium on Plantation Crop Research, Marino Beach Hotel, Colombo, 4-6 November, 2019

- W.D.M. Sampath, I.D. Perera, D.G. Edirisinghe and V.G.M.J. Abhayawardhana “Effect of Waste Polyethylene on Properties of Methyl Salicylate treated Natural Rubber / Low Density Polyethylene / Waste Polyethylene Composites” Proceedings of the Seventh Symposium on Plantation Crop Research, Marino Beach Hotel, Colombo, 4-6 November, 2019.

- Perera, I.D., Etampawala, T.N. and Edirisinghe,D.G. “Development of light coloured, transparent, natural rubber based teething ring using nitrosamine safe accelerators”, Proceedings of the 6th Undergraduate Symposium “UNI-IN ALLIANCE 2020”, University of Sri Jayewardenepura, 28th February, 2020.

- Amali Weerakoon, Laleen Karunanayake and Dilhara Edirisinghe (2020) “Effects of solvent system on the polyphenol extraction from banana (Musa spp. Var. Ambul Kesel) pseudo-stem”, Proceedings of the International Conference on Advances in Computing and Technology (ICACT 2020), University of Kelaniya, 28th November, 2020.

- T.G.K.H. Madushika, U.A. Weerasinghe, D.G. Edirisinghe, A.M.W.K. Senevirathna and E.A.L. Lochana (2021) – “Development of Oil Palm Fiber Waste Filled Natural Rubber Composites” – Presented at the IRCUWU2021, 5th International Research Conference of Uva Wellassa University, 2nd July, 2021.

- Y.G. Kondarage, C.L. Hettiarachchi, D.G. Edirisinghe and W.G.A. Pabasara “Preparation and Optimization of Banana Fiber Reinforced Natural Rubber Composites” – Presented at the IRCUWU2021, 5th International Research Conference of Uva Wellassa University, 2nd July, 2021.

- U.A. Weerasinghe and D.G.Edirisinghe (2021)- “Effect of Dinitroso Pentamethylene Tetramine (DNPT) Loading on Cure Characteristics of Filled and Unfilled Natural Rubber Cellular Compounds”- Presented at the ICMAS 2021, International Research Conference on Multidisciplinary Approaches in Science at University of Colombo, 25th November, 2021.

- Sampath, W.D.M., Fernando, C.A.N. and Edirisinghe, D.G. (2022) – “Synthesis and Characterization of Poly (ethylene glycol)-Grafted Graphite and Graphite Oxide and Comparison with Natural Graphite” - Proceedings of the 10th YSF Symposium, p. 194.

- A.D. Wickramapala, D.G. Edirisinghe, P.K.I.L. Jayarathna, T.A.R.W.M.M.C.G. Bandara and A.M.W.K. Senevirathna (2022). “Suitability of Sesame Oil as an Alternative Processing Aid for Aromatic Oil in Carbon Black Filled Natural Rubber Composites” - Proceedings of the IRCUWU2022, 6th International Research Conference of Uva Wellassa University, 28-29th July 2022, p.250.

- W.D.M. Sampath, C.A.N. Fernando and D.G. Edirisinghe (2022). “Effect of copper grafted graphite loading on cure characteristics of natural rubber composites” - 2nd International Conference on Science and Technology, South Eastern University of Sri Lanka, 24th of August 2022.

- W.D.M. Sampath, C.A.N. Fernando and D.G. Edirisinghe (2022). “Effect of graphite oxide loading on tensile properties of natural rubber composites” - Proceedings of the International Research Conference (IRC), Technological Campus , 29-30th of September 2022.

REVISED TESTING CHARGES – July 2022

Testing charges have been revised with effect from 01.07.2022, as mentioned in the following table.

Note: Please note that Transport charges, Priority charges & Institutional charges have not been added to the toal charges. It should be added to the total charges whenever necessary. Figuers are in LKR.

|

Laboratory Test |

Per Sample (Rs.) |

|

|

1 |

Tensile properties- without preparation of test pieces & without ageing |

800 |

|

|

Tensile properties- without preparation of test pieces & with ageing |

2400 |

|

|

Tensile properties- with preparation of test pieces & without ageing |

900 |

|

|

Tensile properties- with preparation of test pieces & with ageing |

2700 |

|

|

|

|

|

2 |

Tear strength- without preparation of test pieces & without ageing |

800 |

|

|

Tear strength- without preparation of test pieces & with ageing |

2400 |

|

|

Tear strength- with preparation of test pieces & without ageing |

900 |

|

|

Tear strength- with preparation of test pieces & with ageing |

2700 |

|

|

|

|

|

3 |

Hardness- without preparation of test pieces & without ageing |

400 |

|

|

Hardness- without preparation of test pieces & with ageing |

2100 |

|

|

Hardness- with preparation of test pieces & without ageing |

600 |

|

|

Hardness- with preparation of test pieces & with ageing in air |

2200 |

|

|

Hardness- with preparation of test pieces & with ageing in water / ASTM oil |

2500 |

|

|

|

|

|

4 |

Abrasion volume loss -without preparation of test pieces |

900 |

|

|

Abrasion volume loss - with preparation of test pieces |

1000 |

|

|

|

|

|

5 |

Compression set- without preparation of test pieces & without ageing |

400 |

|

|

Compression set- without preparation of test pieces & with ageing |

600 |

|

|

Compression set- with preparation of test pieces & without ageing |

500 |

|

|

Compression set- with preparation of test pieces & with ageing |

900 |

|

|

|

|

|

6 |

Specific gravity |

500 |

|

|

|

|

|

7 |

Resilience- without preparation of test pieces |

200 |

|

|

Resilience- with preparation of test pieces |

400 |

|

|

|

|

|

8 |

Rubber Process Analyzer (RPA) Test- Rheograph / Cure characteristics |

1300 |

|

|

Rubber Process Analyzer (RPA) Test- Strain / Frequency / Temperature sweep |

1300 |

|

|

|

|

|

9 |

Peel strength |

800 |

|

|

|

|

|

10 |

Swelling test at ambient temperature |

800 |

|

|

Swelling test above ambient temperature / Change in volume with ageing |

2500 |

|

|

|

|

|

11 |

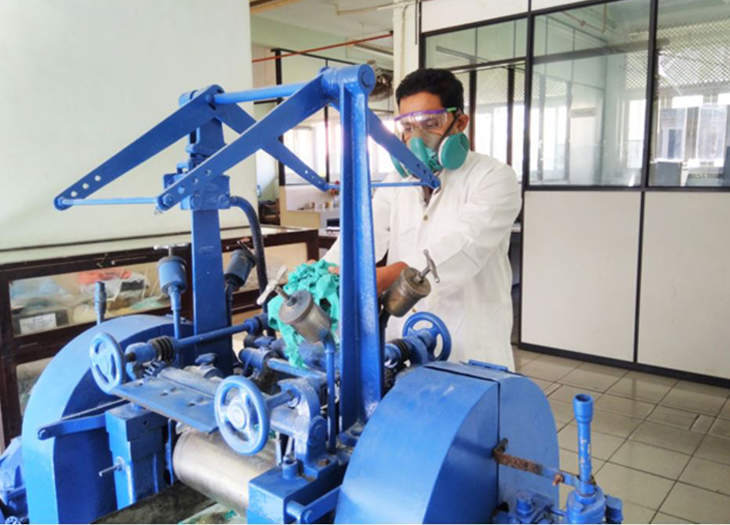

Compounding (Two roll mill- without material charges) per 1kg |

300 |

|

|

Compounding (Two roll mill- with material charges) per 1kg |

900 |

|

|

Compounding (Internal mixer- without material charges) per 1kg |

500 |

|

|

Compounding (Internal mixer- with material charges) per 1kg |

1100 |

Call 1919

Call 1919